The Age

Of Combination Tools

and

The Launch of Paper Bags

In the early 1940's, the war

effort practically halted production of vacuum cleaners as well as new

innovations for accessories. Electrolux's Old Greenwich factory, along

with just about any other factory in the US, had been geared up to

produce parts for the armed forces. While no new vacuums were

manufactured at the peak of WWII, parts for existing machines were

allowed to be made. and

The Launch of Paper Bags

The engineers at Electrolux and many other companies did, however, learn a thing or two from this new role, and would soon come out with some fantastic changes to their product lines.

The model XXX remained the dominant, top of the line model for Electrolux until 1952, when the Model LX was introduced. The LX was a completely new machine in two major ways: It uses new paper "wrappers" (bags), and it automatically ejects the bag once it was full. I've heard that 8 feet was an unofficial world record - must've been pretty exciting! (Hold it right there, mister! I've got a vacuum and I'm not afraid to use it!). We'll get into the new paper bags later, so hang in there.

With the LX came a gamut of accessories - from standard rug and floor tools to sprayers, vaporizers and turbine powered polishers. Talk about accessory heaven! This did have one draw back, however. With all these metal tools carried in a caddy strapped to its back, along with its nice, shiny cord winder, it weighed a ton. Lurking on the horizon was - thankfully - a new, smaller and lighter vacuum; the Model E.

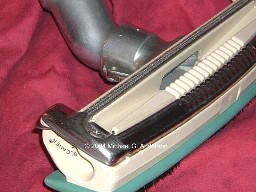

Here is a tool unlike any other, with its strange

flaps sticking up.

Here is a tool unlike any other, with its strange

flaps sticking up.  It also uses a channel

design similar to what can be found in the earlier tear-drop upholstery

tool, good for keeping suction evenly distributed over the surface

area.

It also uses a channel

design similar to what can be found in the earlier tear-drop upholstery

tool, good for keeping suction evenly distributed over the surface

area.

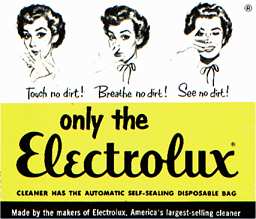

Since the beginning, the vacuum cleaner

has had some kind of cloth bag or filter to collect the dirt that was

vacuumed up.

Since the beginning, the vacuum cleaner

has had some kind of cloth bag or filter to collect the dirt that was

vacuumed up.

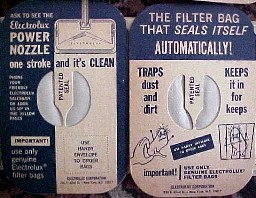

The first paper bags were made from only one-ply

paper, and tended to clog up pretty quickly. A multi-layer bag was

introduced in short order which solved the clogging problem and greatly

improved the air filtering.

The first paper bags were made from only one-ply

paper, and tended to clog up pretty quickly. A multi-layer bag was

introduced in short order which solved the clogging problem and greatly

improved the air filtering.