| Electrolux's

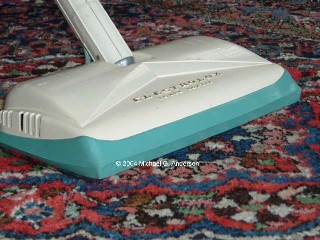

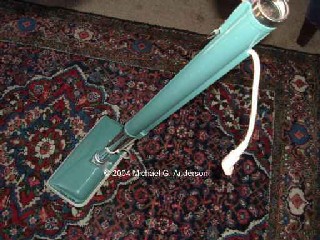

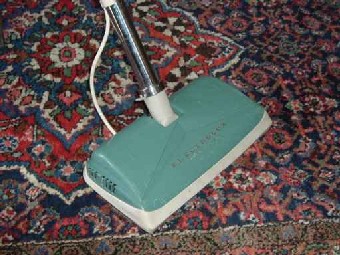

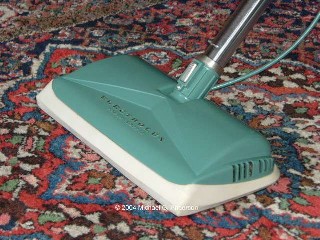

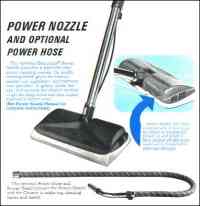

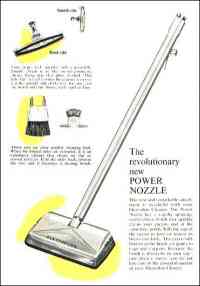

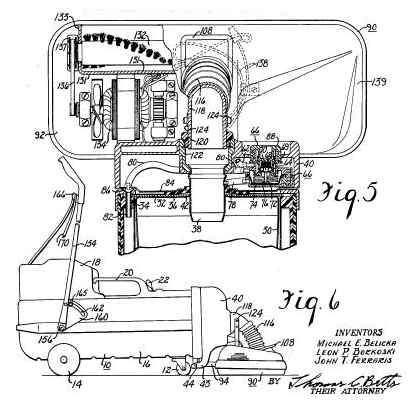

First Power Nozzle: The PN1 The power nozzle for Electrolux, which certainly gets credit for many great innovations, first appears in patents 3039129 and 3039130, invented by Michael E. Belicka [et al], filed in 1959 and awarded in 1962. You can view the patents at http://patft.uspto.gov/netahtml/srchnum.htm In the drawings the nozzle is shown directly attached to the front of a machine similar to the Model F. The nozzle looks just like the actual Power Nozzle #1 (PN1), complete with the very stylish chevron design. Of note is how the nozzle connects to the cleaner. The drawings clearly show that the nozzle is removable, with a very short hose bent between the nozzle and the front of the vacuum. A handle is added to the back of the vacuum so you could push it around like an upright, though it probably would've handled something like very small and heavy pram. Long after Electrolux had been bought out by Consolidated Foods, this idea returns and makes it to market as Electrolux's Discovery Upright in the 1980's. The major difference with the latter is that the canister vacuum is mounted to the handle vertically, instead of a handle attached to a horizontal vacuum. |   |

|